INDIA — Fast-growing label manufacturer Jainytic has charted an extraordinary growth trajectory, from ₹3 crore (US$0.34m0 to ₹40 crore (US$4.51m) in turnover within just three years, powered by its strategic investments in Konica Minolta digital printing and Bobst narrow-web flexo and finishing technologies.

Founded in 2021 by Managing Director Nayan Jain, Jainytic entered commercial production in 2022 with a clear goal: to serve an evolving market demanding speed, flexibility, and premium-quality finishes. “Customers were no longer satisfied with long-run, conventional flexo jobs. They wanted faster turnarounds and more creative freedom,” Jain explained.

To address these needs, Jainytic adopted a hybrid production strategy built around Konica Minolta’s AccurioLabel 230 digital press, supplied and installed by Reifenhäuser and Konica Minolta India. The digital press transformed Jainytic’s operations by enabling same-day sampling and short-run production without plate costs, a critical advantage for startups and small-batch clients.

“Digital changed the way we look at customers,” said Jain. “With flexo, short runs don’t make economic sense. But with digital, we can print 100s of design options quickly and cost-effectively. That flexibility has helped us win new customers and retain them as their volumes grow.”

The AccurioLabel 230, with 1,200 x 1,200 dpi resolution, has allowed Jainytic to cater to high-end markets such as liquor, cosmetics, and FMCG, where color accuracy and shelf appeal are paramount. Jain noted that sampling, once costing clients ₹7,000–₹8,000 and taking days, can now be done at negligible cost on the same day, a decisive factor in customer acquisition and retention.

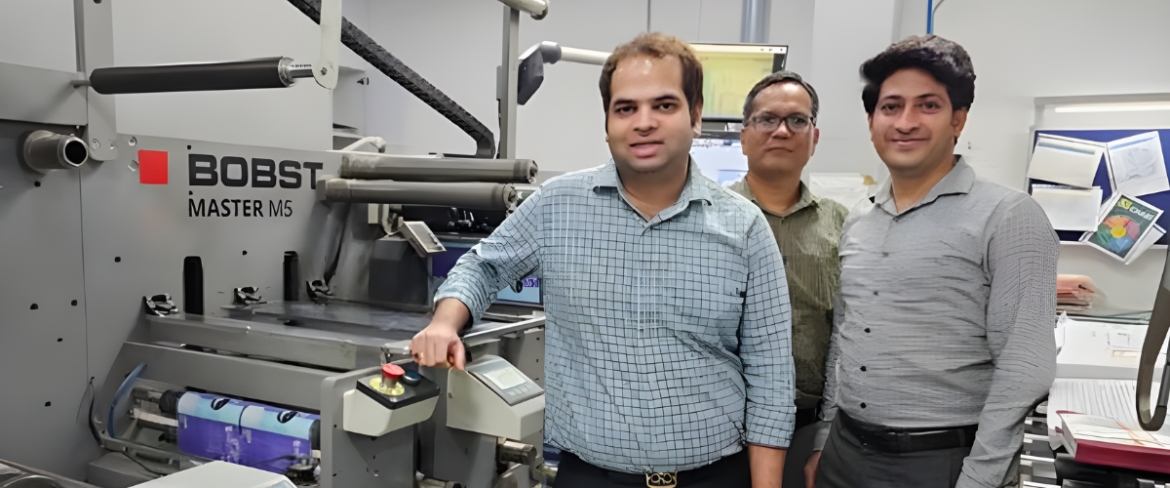

Complementing its digital operations, Jainytic invested in a Bobst narrow-web converting line in 2022 to enhance finishing and embellishment capabilities, including foiling, varnishing, and embossing. This move positioned the company to serve premium segments and diversify its portfolio.

“With Bobst, we can offer high-value decorative effects. We don’t just want to compete on volume; we want to compete on value,” Jain said. Now in the process of relocating to a 2.5-acre site in Ghaziabad, which will house both its label unit and a new injection-moulding plant, Jainytic is preparing for its next phase of expansion. “Every machine we buy is for the future. Our goal is to scale to ₹500 crore (US$56.34m) in the next five years,” Jain affirmed.

Jainytic’s rapid ascent highlights how strategic technology investments, combining digital agility with flexo performance and premium finishing, can redefine competitiveness in India’s dynamic packaging and label industry.

News Courtesy : Sustainable Packaging Middle East & Africa