Komcan Inc. along with KG Graphics Finishers Inc, of Oakville, Ontario, have recently announced the purchase of a new Komori GL640C advance EX with UV curing on a 12” raise with PQA-S camera system to KG’s operations. Complementing a current Komori press, the new Komori will be delivered in Q4 of this year.

KG Graphic Finishers specializes in printing and manufacturing of folding cartons. Owner, Jeff Goberdhan, was in need of a new technology solution to continue their plan for growth and continuous improvement combined with a vision inspection system.

Komori’s PQA-S will allow KG to monitor each sheet that is printed for defects as well as keep them in consistent colour making automatic in-line closed-loop ink key adjustments.

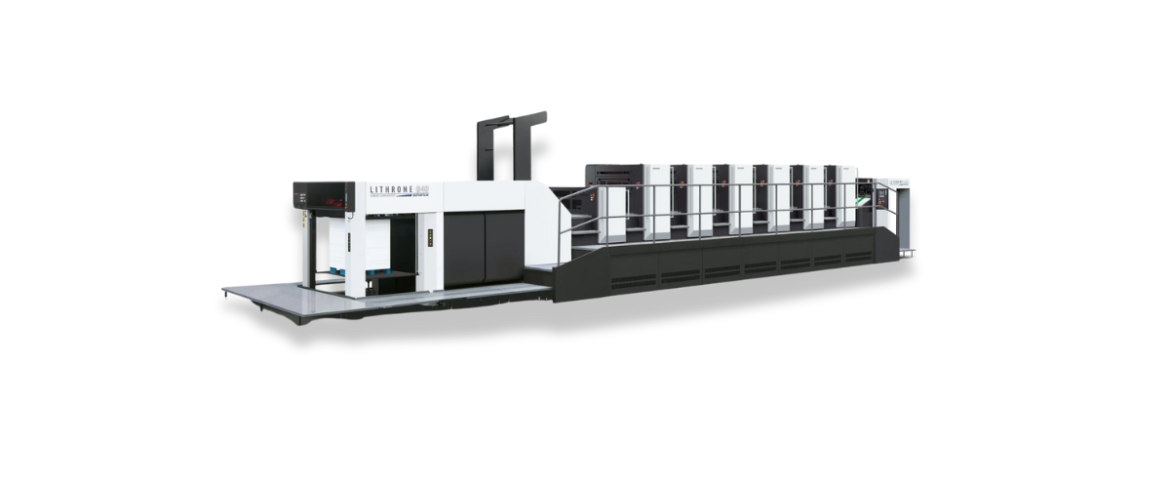

GL640C advance EX with UV + PQA-S

“Adding the Komori GL640C advance EX with PQA-S to our production floor reinforces our commitment to continuous improvement. This technology will drive efficiency, reduce waste, and elevate the level of quality our clients have come to expect from us.” states Jeff Goberdhan from KG Graphic Finishers.”

“When Jeff approached Komcan to expand their capabilities, it was clear that a GL press with PQA was the perfect fit. Jeff’s trust in Komcan to add the new press is the next step in the ongoing partnership and ensures KG’s capabilities to expand their capabilities to their customers.”, says Brad Ranson of Komcan.

Jeff Goberdhan – Owner

Automation and Reliability were key factors in the decision, as the Komori GL640C utilizes such automation features as Fully Automatic Plate Changers, PDC-SX Closed Loop Colour Control, Komori’s Automatic Makeready System (AMR), PQA-S Camera system, as well as KHS-AI – Komori’s productivity enhancement system, which automatically optimizes various press presets by self-learning.